Home › EIDA Forum › Today’s Discussion and Announcements › CVX Semiconductors Opens in Adelaide

- This topic has 0 replies, 1 voice, and was last updated 5 years, 9 months ago by

Tingting Zhang.

-

AuthorPosts

-

-

at #3687

Tingting Zhang

KeymasterHong Kong firm CVX Semiconductor will establish an engineering and research capability in Adelaide, including a reliability testing laboratory. CVX specialises in next generation power electronic devices and circuits and it is a joint venture between Hong Kong’s VX-Power and Canaan Semiconductor.

CVX Semiconductor plans to expand its operations and begin manufacturing wide bandgap devices, a growing global market segment for components used in products such as electric vehicle charging stations and wireless phone chargers.

CTO of CVX, Dr Ted Kok, says that the company is establishing its research and development centre in Adelaide in order to access and work with the high quality engineering capabilities and universities here. “We’re delighted to already be working on various R&D projects and post graduate students’ work which will train new streams of workers and support the innovation of next-generation products from South Australia.”

The CVX Pty Ltd website shows: “Although we are a startup in Adelaide Australia, we are not new to the industry. Our engineers and management have an average of more than 10 years-experience in semiconductors. They have helped to innovate the latest generation of power electronics integrated circuits and devices, and will continue in this energetic startup.”

The company, which already has on-the-ground staff at Stone & Chalk and Lot Fourteen in Adelaide, will use the SA Government Landing Pad Program to explore more permanent accommodation and manage migration of key talent to the state in order to start local technology transfer and research development projects with universities and businesses. Eventually, the company plans to establish offices and manufacturing capabilities at the Tonsley Innovation District in South Australia.

CVX plans to grow its initial employee base to approximately six, but with its key testing and manufacturing activities still to be developed, it has plans to expand this number to around 50 over the next five years.

Wide bandgap devices

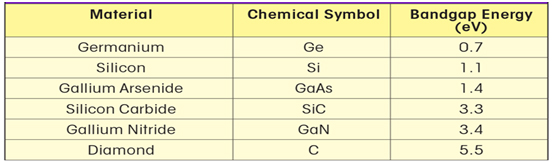

Silicon’s 20th Century dominance in power electronics applications has been eroding for some time now. As engineers extract dwindling amounts of additional performance from silicon ICs, they are looking to wide-bandgap (WBG) materials to develop next-generation power electronics. Examples include silicon carbide (SiC) and gallium nitride (GaN). Materials that have a wide bandgap are inherently applicable in high-power electronics, as they have a higher breakdown voltage and are able to run at higher temperatures when compared to materials with narrow bandgaps, such as silicon.

See: electronicdesign.com

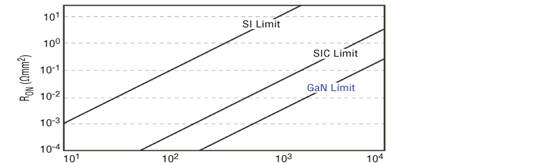

SiC and GaN also offer the potential for smaller, more robust power devices, which switch faster and are more energy-efficient than Si-based devices. SiC and GaN products, in demand for electric-car and mobile-device applications, perform much better than Si in reducing on-state resistance and shrinking package size. This results in faster charging, lower power consumption, and more efficient energy conversion. Generally speaking, SiC power semiconductor devices are being specified for applications with high power capacity (in excess of 600 V) and GaN for applications involving medium to low-power capacities.

Silicon carbide has become an attractive alternative to Si in applications requiring efficient high-voltage, high-frequency power conversions. SiC power devices operate at higher switching speeds and higher temperatures with lower losses than conventional silicon. In addition, SiC allows inverters and other energy-conversion systems to be built with improved power density and energy efficiency at lower cost. Almost all the OEMs and Tier-1s are using or testing SiC devices in electric and hybrid electric vehicles (EVs and HEVs).

WideBreakdown voltage for Si, SiC, and GaN

Similarly, GaN possesses high breakdown voltage and low conduction resistance characteristics, thereby enabling high-speed switching and miniaturization. Unlike conventional Si transistors, which require bigger chip areas to reduce on-resistance, GaN devices have smaller sizes (and lower parasitic capacitance) for high-speed switching. Miniaturization is possible in part because of the smaller passive components needed.

Let’s now look at recent developments in SiC and GaN one at a time. Infineon states: The key for the next essential step towards an energy-efficient world lies in the use of new materials, such as wide bandgap semiconductors which allow for greater power efficiency, smaller size, lighter weight, lower overall cost – or all of these together. Infineon Technologies with its unique position of being the only company currently offering silicon (Si), silicon carbide (SiC), insulated-gate bipolar transistor (IGBT) and gallium nitride (GaN) devices, is the customer’s first choice in all segments.

As evidence of the growing maturity of WBG materials, JEDEC-a global leader in developing open standards for the microelectronics industry-just formed a new committee: JC-70 ‘Wide Bandgap Power Electronic Conversion Semiconductors.’ This team is helping to create the mature industry infrastructure that customers need to design power supplies. Led by interim chairs from Infineon, Texas Instruments, and Wolfspeed, the new JC-70 committee will initially have two subcommittees (yes, you guessed it): Gallium Nitride and Silicon Carbide. Both will focus on Reliability and Qualification Procedures, Datasheet Elements and Parameters, and Test and Characterization Methods.

-

-

AuthorPosts

- You must be logged in to reply to this topic.